This blog post was originally sent as an email update to our mailing list on 02/07/2022, an image was added to this post which wasn't part of the email.

Hi,

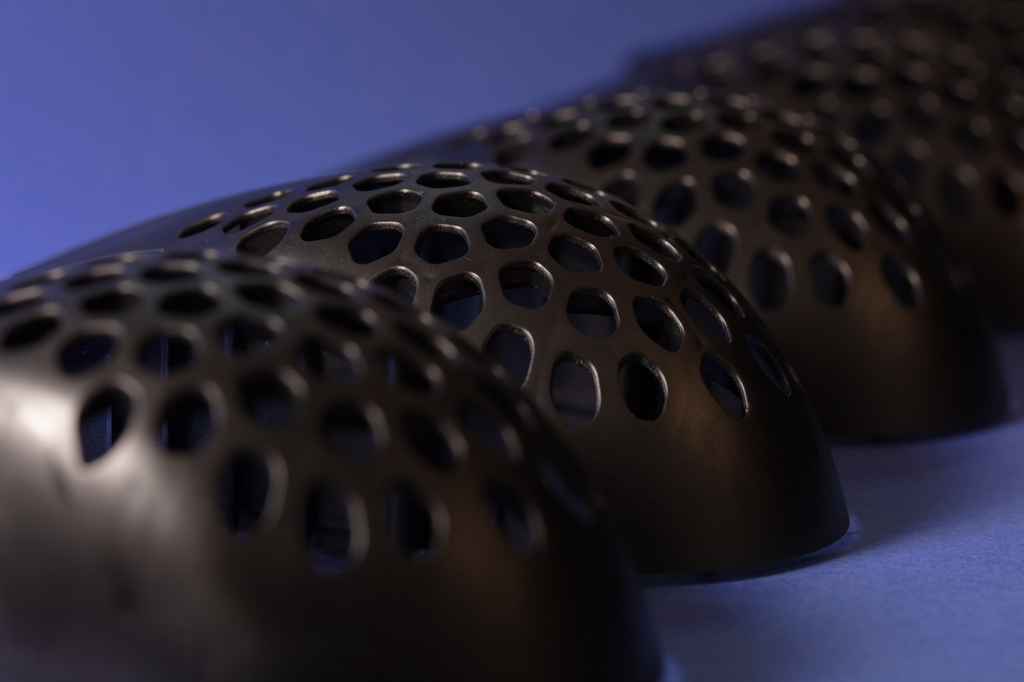

I'm happy to announce a major milestone for Atompalm which brings us much closer to the release day. After a lengthy process of iterating prototypes last year, we submitted our designs to our injection molding partner. Just last week the molds were finished, and the first batch of sample parts was sent to us -- they look amazing!

As these are just the first samples from a newly machined mold, there are some minor cosmetic issues that we're ironing out before mass-producing the final product.

Injection molding is the process of making plastic components by injecting hot liquid plastic at high pressure into a mold. A mold is basically a "negative" of the component, i.e., a big block of steel which has a the shape of the component cut out of it. A mold is not one solid block though, it's multiple pieces which are pressed together before the plastic is injected, and then pulled apart once the plastic has solidified to reveal a completed component.

Since injection molding deals with hot plastic in a mold with many varying thicknesses, it's difficult to predict exactly how the plastic will contract as it cools and solidifies. The main issue that occurs is what's called a "sink mark," which is a tiny dip on an otherwise flat surface.

If you look closely in the photo of the backs of the top shell you can see some small sink marks between the pentagons. There are a few even more minor cosmetic issues that we're addressing before we get into the final production.

One thing I'm happily relieved about is that the mechanical fit between the top shell, bottom skate, and side buttons is perfect. We were prepared to deal with some issues there but, for once, there were none :)

I hope you enjoyed this glimpse of the final product. This is an email I've been eager to write because injection molded plastics have been a major barrier to release for a long time. With that out of the way, we're one huge step closer to getting the mouse in your hand!

Cheers --

Dimitar Dimitrov

Founder, Atompalm.